Trwy TransMet ®mae prosesau materion copad yn ychwanegu dim ond 7gsm o wely yn rhannol â chopad filmiau a chopad alffiniau, sy'n ychwanegu'n leiaf 20gsm ar y papur sylfaen.

Gwirio Cynllun Cyfradd: TransMet ®vs copad filmiau & copad alffiniau

1)Lleihau 100% ffilm plastig (ddelweddau fossill )defnydd ar gopad.

Mae'r ffilm plastig yn bennaf ei wneud o delweddau fossill, mae'n cael ei feddwl yn gyffredinol bod delweddau fossill yn adnodd cyfyngedig.

Copad filmiau gyda leiaf 20gsm o wely yn ychwanegu oherwydd copad llif ffilm plastig 12/15U ar y papur sylfaen wrth i TransMet ®materion copad heb unrhyw ffilm plastig ar y copad wedi'i gwblhau.

2)Lleihau 99.5% ffol alffiniwm (adnodd mynrol )defnydd ar gopad.

Mae'r ffol alffiniwm yn metel a wnaed o mynrol, mae'n cael ei feddwl yn gyffredinol bod mynrol yn adnodd cyfyngedig.

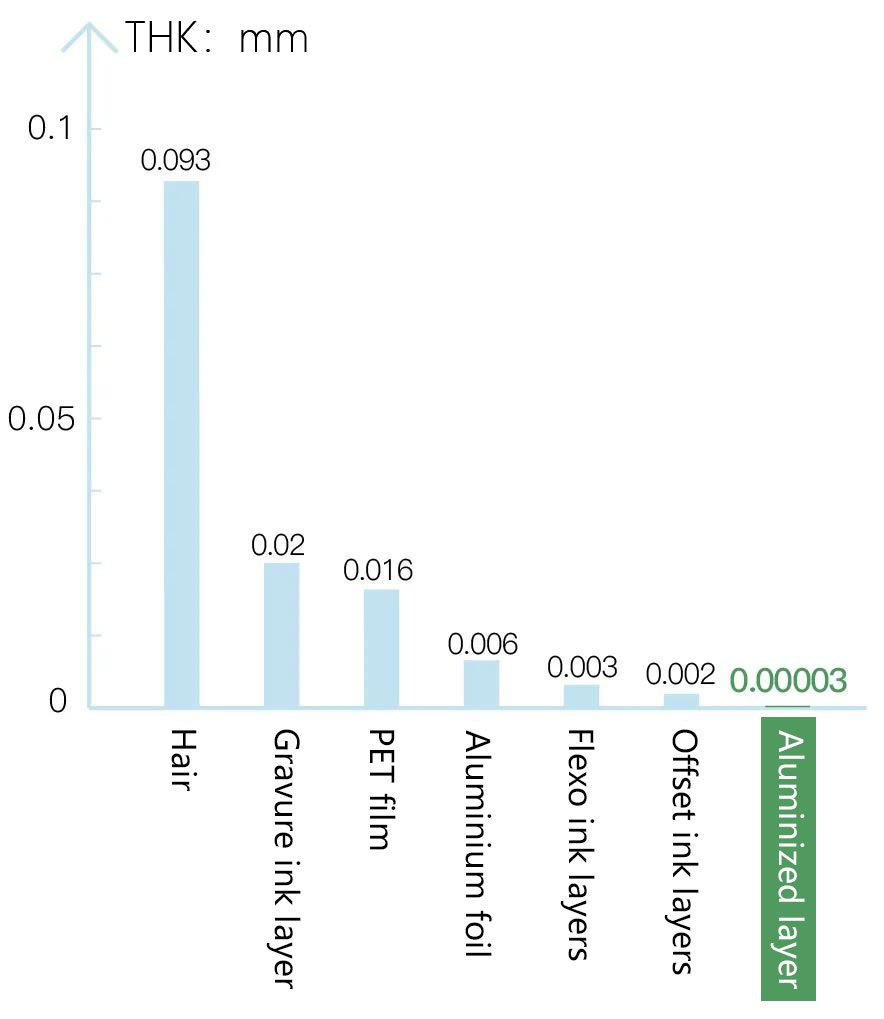

Copad alffiniau gyda leiaf 20gsm o wely yn ychwanegu oherwydd lywr ffol alffiniwm 6/6.5 micron yn cael ei chopad ar y papur sylfaen wrth i TransMet ®materion copad yn unig ei metalu bach gyda thichniethdod 30 nanometr o lywr alffiniwm ar y copad wedi'i gwblhau.

Gwiriwch faint yw TransMet yn tyb ®tegyn metel:

Yn gyffredinol o leiaf 65% adnodd amserol (carburau a thruslyfr )wedi eu cadw (7gsm yn gwyn i 20gsm) os ydych yn dewis TransMet ®materialedd paciadau.