แต่เมื่อเราซื้อโลชั่นที่เรารัก ลิปสติกหรือน้ำหอมโปรดของเรา และผลิตภัณฑ์ความงามชนิดอื่น ๆ เราเคยคิดไหมว่าบรรจุภัณฑ์ของพวกมันนั้นยอดเยี่ยมเพียงใด ผลิตภัณฑ์เป็นเพียงสิ่งที่บรรจุภัณฑ์เก็บรักษาให้ปลอดภัยและดูดี รับประกันคุณภาพของผลิตภัณฑ์ไม่ให้เสียหาย บริษัทผู้ผลิตบรรจุภัณฑ์เครื่องสำอางเชี่ยวชาญในการทำกล่องและภาชนะที่สามารถใช้งานได้จริงและมีสไตล์เพื่อความสะดวกของผู้บริโภค

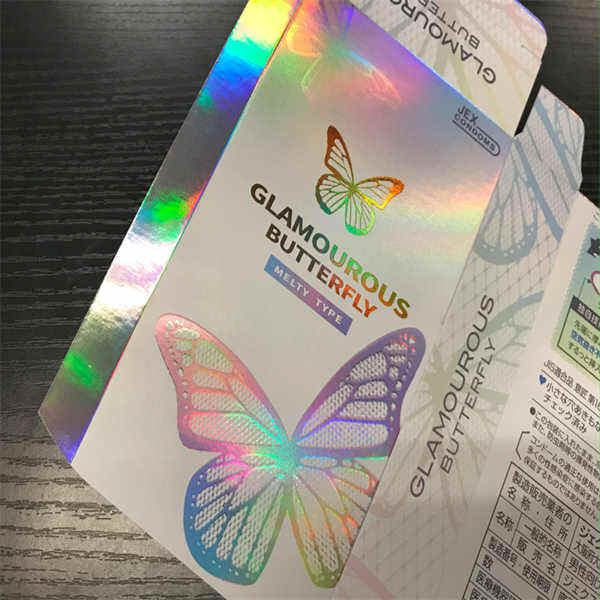

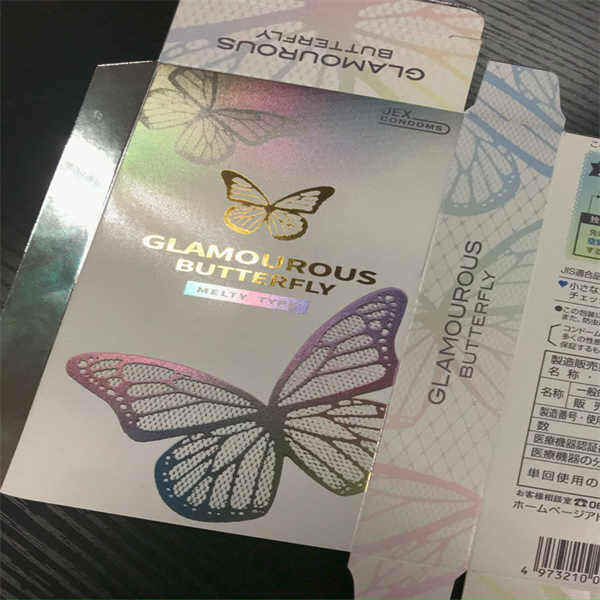

บริษัทเหล่านี้ผลิตบรรจุภัณฑ์จากวัสดุต่าง ๆ เช่น พลาสติก แก้ว เหล็ก เป็นต้น เนื่องจากแต่ละวัสดุมีคุณสมบัติเฉพาะตัว จึงทำให้เหมาะกับประเภทของผลิตภัณฑ์ความงามหลากหลายชนิด พวกเขาผลิตในรูปทรงและขนาดต่าง ๆ สำหรับผลิตภัณฑ์ความงามทุกประเภท บรรจุภัณฑ์อาจเป็นขวด กระปุก หลอด หรือกล่อง และทั้งหมดถูกออกแบบมาเพื่อนำเสนอผลิตภัณฑ์อย่างโดดเด่นบนชั้นวางและปกป้องสิ่งที่อยู่ภายใน

นอกจากนี้ บรรจุภัณฑ์มีบทบาทสำคัญ因为它ป้องกันผลิตภัณฑ์ความงามและรับผิดชอบในการรักษาความสวยงามของผลิตภัณฑ์ ในขณะที่บริษัทบรรจุภัณฑ์เครื่องสำอางกำลังทำงานเพื่อให้มั่นใจว่าวัสดุของพวกเขาแข็งแรง สามารถรีไซเคิลได้ และเป็นมิตรต่อสิ่งแวดล้อม อีกทั้งยังมีการเน้นไปที่บรรจุภัณฑ์ที่สะดวกต่อการจัดการและรีไซเคิลง่าย ซึ่งต้องใช้ความพยายามจากผู้บริโภคน้อยลง

การบรรจุภัณฑ์อัจฉริยะเป็นการพัฒนาอีกทางที่น่าจับตามองในด้านการบรรจุภัณฑ์เครื่องสำอาง/ยา บรรจุภัณฑ์อัจฉริยะสามารถมีปฏิสัมพันธ์กับผลิตภัณฑ์และผู้ใช้ได้เนื่องจากเทคโนโลยีเฉพาะตัว นอกจากนี้ยังมีบรรจุภัณฑ์อัจฉริยะประเภทอื่นที่อาจมีเซนเซอร์ซึ่งสามารถบอกได้ว่าครีมทาหน้าในกระปุกของคุณใกล้จะหมดหรือเสียแล้ว อีกทั้งบางบรรจุภัณฑ์อัจฉริยะสามารถเปลี่ยนเฉดสีหรือสีเมื่อตอบสนองต่อปัจจัยภายนอกเฉพาะ เช่น แสงแดด ทำให้ประสบการณ์การใช้งานน่าสนใจและเพลิดเพลินมากขึ้น

มีทักษะและความรู้มากมายที่เกี่ยวข้องในการสร้างบรรจุภัณฑ์เครื่องสำอางคุณภาพสูง ผลิตภัณฑ์ความงามถูกสร้างสรรค์โดยบริษัท แต่หลังจากนั้นพวกเขาจะรวบรวมผู้เชี่ยวชาญมาพัฒนาบรรจุภัณฑ์ที่จะผสมผสานได้ดีที่สุดกับสินค้าความงามหลากหลาย ทีมออกแบบและการวิศวกรรม อาจจะรวมถึงวิศวกรการผลิตด้วย (ขึ้นอยู่กับสถานการณ์ของโครงการ) เป็นอีกส่วนสำคัญที่จะช่วยให้มั่นใจถึงความสำเร็จ

งานของนักออกแบบคือการพัฒนาการออกแบบบรรจุภัณฑ์ เขายังดูแลให้แน่ใจว่าการออกแบบเป็นการสะท้อนภาพลักษณ์ของแบรนด์และอุทธรณ์ในตลาดได้อย่างถูกต้อง วิศวกรจะตรวจสอบว่าการออกแบบสามารถทำได้จริงและเหมาะสมกับการผลิต ผู้เชี่ยวชาญด้านการผลิตกำกับกระบวนการผลิตทั้งหมดเพื่อให้แน่ใจว่าบรรจุภัณฑ์ถูกผลิตตามข้อกำหนดของการออกแบบและมาตรฐานคุณภาพได้รับการปฏิบัติตาม

ผู้ผลิตบรรจุภัณฑ์เครื่องสำอางยังคงรักษาความยั่งยืนขณะลดขยะโดยรวมผ่านโปรแกรมรีไซเคิลฉลากที่มีประสิทธิภาพ ซึ่งเกี่ยวข้องกับการออกแบบบรรจุภัณฑ์ขนาดเล็ก น้ำหนักเบา และเรียบง่ายที่ลดการใช้วัสดุ นอกจากนี้พวกเขายังส่งเสริมการรีไซเคิลด้วยการทำให้บรรจุภัณฑ์ของพวกเขาสามารถรีไซเคิลได้ หรือใช้วัสดุรีไซเคิลในการผลิตบรรจุภัณฑ์

ประสบการณ์ในด้านการค้าระหว่างประเทศมากกว่า 20 ปี กำลังการผลิตประจำปีของกระดาษพิมพ์เลเซอร์สำหรับผู้ผลิตบรรจุภัณฑ์เครื่องสำอาง 200 ตัน

พร้อมใบรับรอง FSC, REACH, FDA 21 CFR 176.170, (EU) No 10/2011, TUV OK สำหรับผู้ผลิตบรรจุภัณฑ์เครื่องสำอาง RECYCLABLE, ISO 9001/14001/45001, CNAS, PATENTS และใบรับรองด้านสิ่งแวดล้อมอื่น ๆ

ลูกค้าส่วนใหญ่ของเรามาจากบริษัทผู้ผลิตบรรจุภัณฑ์เครื่องสำอางชั้นนำ 500 แห่งของโลก

ผู้ผลิตบรรจุภัณฑ์เครื่องสำอางสำหรับภาษาอังกฤษ ภาษาสเปน และภาษาญี่ปุ่นมีให้บริการ