Why is TransMet so environmentally friendly?

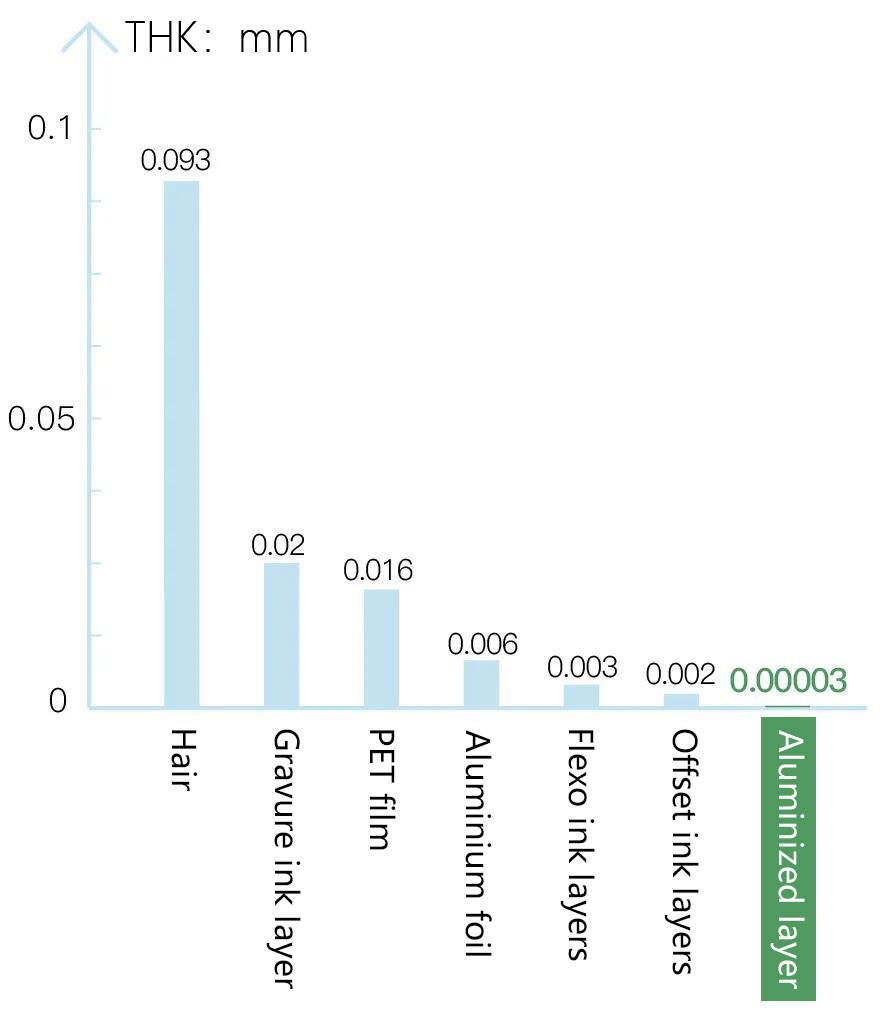

During the production of TransMet® packaging board, we only use PET film as a carrier to paint vaporized alum metal onto material paperboard, the final product of TransMet® board does not carry any of PET. Therefore, The PET film can be reused several times for production and be recycled in the end. More importantly, TransMet® board is produced with vacuum aluminizing technology, with this technology; we could save considerable aluminum usage during production compare to traditional product of Alum Foil laminated board. The alum layer carried by TransMet® board is incredibly thin. Let us have a look at the chart below to see how thin is it.

The thickness of alum layer on TransMet® board is only 1/200 of the thickness on Alum Foil Laminated board. So in conclusion, TransMet® board largely saves 2 materials: plastic film and alum metal. Less plastic usage means less petro consumption, less aluminum usage means fewer mineral and less energy needed.

Now let us talk about a topic that might interest you. How is the carbon emission of TransMet® board? Dose it match with global carbon emission reducing plan of 2030?

Let us continue focusing on the comparison between TransMet® board, Alum Foil laminated board and PET laminated board. As we already know, TransMet® board has an ultra-thin layer of alum metal, which means the usage of aluminum is significantly reduced. Plus, reusable PET film reduces the consumption of plastic. These two advantages allow the production of TransMet® board reduce carbon emission. How much does it reduce then? Let us do a little math.

For example, if we need to produce 1000㎡ of Alum Foil laminated board, Pet laminated board and TransMet® board separately. How much carbon emission will each of them produce?

| Aluminium foil laminated paper | PET laminated paper | TransMet® board | |

| Carbon Emission | 207.36 kg | 49.95 kg | 10.89 kg |

| Equivalent trees | 11.5 trees | 2.8 trees | 0.6 trees |

Hint: above data come from the scenario that all three types of board are made from the same base board; 1 tree absorbs about 18kg carbon emission.

Compare to Alum Foil laminated board and Pet laminated board, TransMet® board’s production contributes 11 or 2 trees. Moreover, we use RTO system (Regenerative Thermal Oxidizer) during the production process. This system allows us to convert carbon emission into electricity to power our machines. According to our data, this system could save about 30% of our electricity consumption. It saves the energy while reduces the carbon emission.

Great Adaptability:

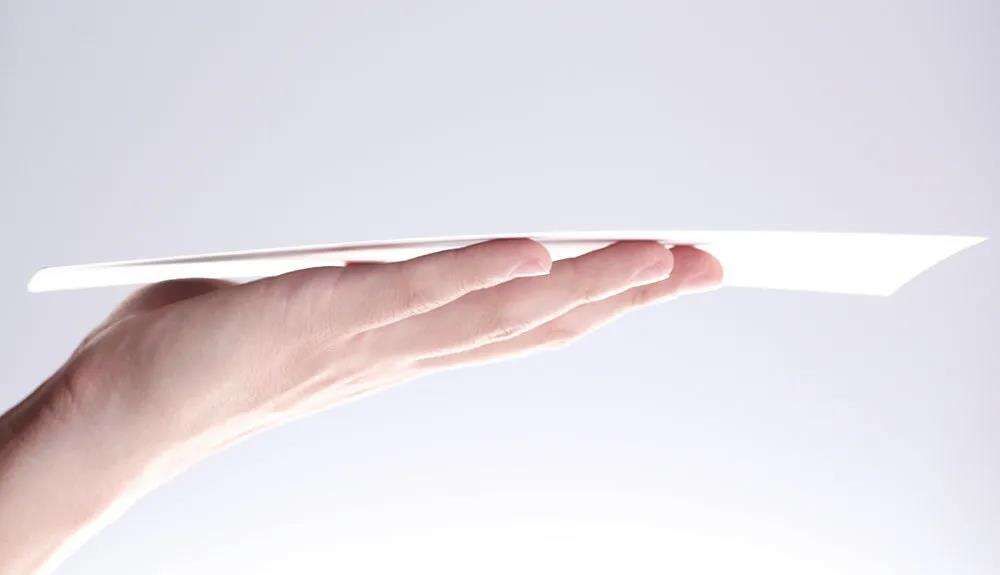

In addition to its eco-friendly advantage, TransMet® board also has a great processing adaptability. It can be used for many sorts of printing technique, such as gravure printing, offset printing, flexo printing, digital printing and so on. The ultra-thin layer of alum on its surface will not change the nature of the paperboard. Such as moisture content, water absorption, board shape, will stay the same just as the material paperboard. Each sheet of TransMet® board will keep its balanced status, no curling, just like white ivory board. It is because of this balanced status, TransMet® sheets can adapt a printing and packing speed, which is 10% faster than the speed can be adapted by Alum Foil Laminated board and Pet Laminated board. In China, the fastest printing machine can go 366 meter/min; the fastest packing machine goes up to 1000 pack/min. TransMet® board has great performance on both fast machines.

—— CASE STUDY ——

1、CHUNGHWA

Chunghwa is famous not only in China, but also worldwide. In 2000, in order to keep up with China’s policy of being eco-friendly, Chunghwa changed its cigarettes’ packaging board into TransMet®. Meanwhile, after China entered WTO, Chunghwa was instructed by the authority to amplify the production by 6 times to meet China’s WTO policy. But yet, the alum metal consumption used for its packaging only amounts up to 1/200 as before. In order to meet the production requirement, the printing and packaging speed is increased significantly, TransMet® board perfectly overcomes this challenge. We could see this case as an evidence that shows TransMet® board is both eco-friendly and efficient. As a product being sold for 70 years, we still could see its eye-catching, good-looking packages shinning in the shops.

2、Neutrogena

In 2008, JNJ launched a series of high-end skin whitening product. To match the high-end marketing image, also in consideration to its eco-friendly social responsibility, JNJ decided to choose TransMet® board for their new products’ packaging. In the meantime, JNJ also made their policy to reduce the usage of PET and Alum Foil laminated material for their packages. This idea of being more eco-friendly and sustainable is still insisted by JNJ as their promise of social responsibility.

We would like to make a proposal in the end.

We hope everyone could join us, to take your part in this Fashion of Green Style movement.